View this article on Business Facilities.

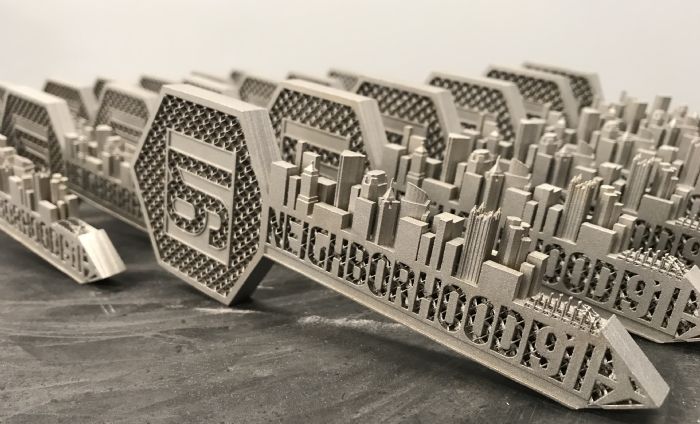

Cumberland Additive will leverage recent growth in the aerospace, defense, and space sectors by expanding operations to the Neighborhood 91 (N91) Additive Manufacturing (AM) production campus at Pittsburgh International Airport. The expansion is an opportunity for Cumberland to grow its core competencies in metal 3D printing and CNC machining while benefiting customers with the turnkey value-added solutions offered by the Neighborhood 91 AM ecosystem.

Cumberland Additive, headquartered in Pflugerville, TX, is an established force in the AM industry, offering series production of parts and engineering design services in both metals and polymer materials using Powder Bed Fusion technology. Both locations will continue to serve major markets such as aerospace, defense, space, energy, and nuclear industries.

“Consolidating the supply chain for AM at the innovative Neighborhood 91 production campus helps us mitigate risks, costs, and complexities for our customers,” commented Cumberland Additive President John Jenkins. “We’re excited to be part of the neighborhood to work together to further ignite the industry.”

In anticipation of the move, Cumberland is developing a relationship with N91 anchor tenant Wabtec Corp. to support its CNC machining needs for complex AM parts. This relationship will enable Wabtec and Cumberland to leverage each other’s technical “know-how” and manufacturing capabilities to unlock the value of AM for their respective non-competing markets.

“We are pleased to welcome Cumberland Additive to Neighborhood 91,” said Philip Moslener, Vice President of Advanced Technologies at Wabtec. “Cumberland is an established additive manufacturing supplier, who brings a unique expertise and skillset. Their addition to Neighborhood 91 will build upon the collaborative spirit of this community and accelerate the development, adoption and application of additive technology.”

By providing a physical location at N91, Cumberland plans to work with local universities and workforce development agencies to train workers to support the growing AM industry.

“Pittsburgh has always had a strong manufacturing culture, and Cumberland will be able to tap into this skilled workforce to quickly grow its production capacity,” said Cumberland Additive Chairperson Dawne Hickton, a Pittsburgh native.

According to one of the original visionaries for Neighborhood 91, AM leader John Barnes, founder of The Barnes Global Advisors, the addition of Cumberland fulfills the next step in the evolution of the campus.

“As a part manufacturer, Cumberland Additive joins Wabtec as an anchor tenant forming the foundation of the Neighborhood 91 supply chain strategy,” said Barnes. “These manufacturers will drive the need for the next tenants who will provide powder, thermal treatment, testing, and analysis on campus.”

We are delighted that Cumberland will be the latest manufacturing anchor tenant in Neighborhood 91,” said Allegheny County Executive Rich Fitzgerald. “The fact that this development is continuing to attract companies, not just those which are local, but companies from across the country, is a testament to the strength of our region and the vision of Neighborhood 91. Thanks to Cumberland for choosing the Pittsburgh region for this expansion, and welcome to the Neighborhood.”

“Cumberland’s announcement is another example of how the vision for Neighborhood 91 to be a global headquarters of additive manufacturing is becoming a reality,” said Pittsburgh International Airport CEO Christina Cassotis. “Cumberland is another manufacturing anchor tenant – choosing to expand in Pittsburgh at Neighborhood 91 – which will help attract more companies. I’d like to welcome Cumberland and look forward to continued partnership.”

With the execution of the Neighborhood 91 lease agreement, Cumberland expects to be fully operational by Q4 of this year. This expansion also enables a focus on large format machines, including the EOS M 400-4, an SLM®500 and redundant capabilities such as the Arcam EBM Q20plus for metals, along with an EOS INTEGRA P 450 for polymer materials.